Excavator Plate Compactor

Home » Our Products » Construction Equipment » Excavator Plate Compactor

Explore the diverse applications of the excavator plate compactor, including trench compaction, slope stabilization, and more, ensuring optimal soil density and stability.

The Excavator Plate Compactor is a specially designed attachment that can be easily mounted on any excavator or backhoe loader. Engineered for challenging applications, it is ideal for canal and dam slope compaction, railway track extensions, and other projects involving sloped or hard-to-reach surfaces where conventional compactors are not effective.

This powerful attachment enables deeper and more precise compaction in areas inaccessible to standard compactors, making it an essential tool for contractors working on complex terrain and infrastructure projects.

The Hydraulic Plate Compactor is compatible with a wide range of excavators and skid loaders, including popular brands such as KOMATSU, CAT, HITACHI, KOBELCO, DOOSAN, DAEWOO, JCB, OKB, NPK, MKB, LIUGONG, XCMG, LIEBHERR, HYUNDAI, SUMITOMO, YANMAR, KUBOTA, IHISCE, TAKEUCHI, and many more.

We are dedicated to ongoing innovation and refinement of our products to exceed client expectations consistently.

At Trinity Solutions, our unwavering commitment to continuous innovation and product refinement is central to our mission of consistently exceeding client expectations. By actively seeking and embracing customer feedback, we gain valuable insights into areas for improvement, allowing us to tailor our products and services to better meet our clients’ needs .

Key Features & Benefits :

- Compacts space where no other compactor can reach

- Easy Quick Compaction

- 3 Different models from 5 to 65 tons are available

- Oil Bath Type compaction weight chamber is filled with gear oil. Periodic greasing and oil changing interval is 365 days.

- Single hose block: All hoses are routed within the frame and connected to a mono hose block. Preventing the hoses from damage.

- Self-aligning bearing, provides a long service life to rotating components.

Application :

- Irrigation Canals

- Road Railways

- Trench Compaction

- Embankments

- Water Sewage

Technical Specifications :

| DESCRIPTION | DIP 100 | DIP 200 | DIP 400 |

|---|---|---|---|

| Recommended Carrier Weight | 5 to 15 Tons | 7 to 25 Tons | 25 to 65 Tons |

| Operating Weight | 362 kg | 650 kg | 1000 kg |

| Operating Weight | 49-91 LPM | 49-114 LPM | 91-159 LPM |

| Dynamic Force | 2.9 Ton | 5 Ton | 9.5 Ton |

| Frequency | 2000 vpm | 2000.vpm | 2000 vpm |

| Base Plate Size | 600 mm x 800 mm | 670 mm x 880 mm | 800 mm x 1100 mm |

| Height | 570 mm | 620 mm | 650 mm |

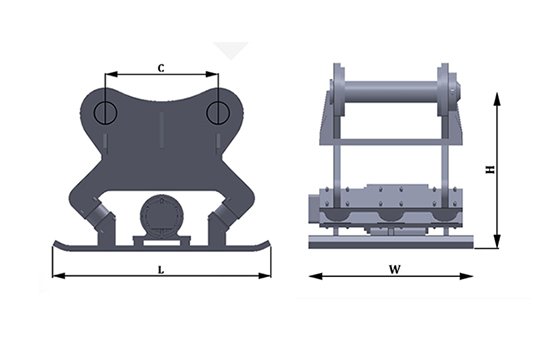

| L | W | H | C | |

| DIP 100 | 800 | 600 | 570 | 465 |

| DIP 200 | 880 | 670 | 620 | 465 |

| DIP 400 | 1100 | 800 | 650 | 465 |

drawing of the excavator plate compactor