Sewage Treatment Plant (STP)

Home » Our Products » Sewage Treatment Plant (STP)

Trinity Sewage Treatment Plant (STP) – Sustainable Wastewater Solutions

The STP is designed to treat normal municipal sewage water using biodegradable and sedimentation technology. The system is specifically engineered to be containerized in standard shipping containers and arrive at the site ready for connection to influent and effluent piping and an electrical power supply. The motors and instrumentation can be supplied to run on the customers’ power system if it is different from the standard 240/480 V 60 Hz supply.

The system will be designed to meet the existing requirements of capacity, influent chemical conditions and effluent requirements. The system is not intended to produce potable water as the effluent but to meet standards to allow effluent to be used as irrigation water under the existing governing guidelines.

External tanks and equipment that normally fall under the customer’s scope can be designed and supplied unassembled. Typical spare equipment for two years operation will be provided with initial set up.

Sewage treatment is the process of removing contaminants from wastewater and household sewage. Its objective is to produce an environmentally safe fluid waste stream. Sewage treatment usually works in three stages: primary, secondary, and tertiary. The primary treatment removes heavy solids. Then the secondary treatment involves the addition of micro-organisms that dissolve the suspended matter in the sewage. The final or tertiary stage removes any residual matter and disinfects the water.

We are dedicated to ongoing innovation and refinement of our products to exceed client expectations consistently.

At Trinity Solutions, our unwavering commitment to continuous innovation and product refinement is central to our mission of consistently exceeding client expectations. By actively seeking and embracing customer feedback, we gain valuable insights into areas for improvement, allowing us to tailor our products and services to better meet our clients’ needs .

Our Products

General Description Of The STP-Plant :

The STP is based on the biodegradation and sedimentation technology, which is unique due to its compactness and performance.

Proformance Ctiteria

All treatment plants shall be based on actual measurements of the waste stream to be treated with respect to the volumetric load, suspended and dissolved organic material, and the applicable local effluent requirements.

Pre-Sedimentation System

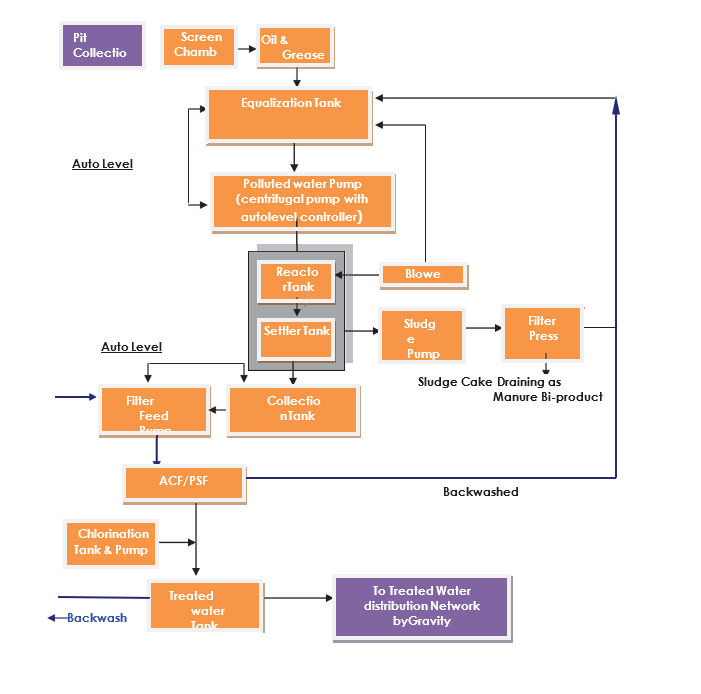

It is assumed that the polluted domestic water piping system ends in a customer provided pump well/tank system which shall be preceded by a screen chamber and oil and grease trap. The system shall ensure that grit, floating matter, oils and coarse particles which shall hinder the operation of the plant equipment are separated before the process.

The buffer capacity must be sufficient to level out the daily peak flows.

BiologicaI Treatment System

The treatment plant will take suction from the pump well by its own feed pump. The pump is auto level controlled and has a capacity, which is slightly higher than the average daily flow. The plant has, therefore, an intermittent working mode in terms of hydraulic flow, while the air blower supplying air to the bioreactors is continuous. The bioreactors degrade the dissolved organic matter by oxidation into carbon dioxide, which escapes to the air, and to biomass that acts as activated sludge.

A suspended, free-floating bio-film carrier medium provides a large, protected bio-film surface for the bacteria and simultaneously accumulates the active bio-sludge inside the reactors.

Sludge Separation System

The biodegraded water flows to a clarification stage where the suspended solid settles by gravity. The water is directed to a skim well to tube settler system which provides the final clarification of the effluent.

The sludge pump is activated with suction from the clarification stage. The pump discharges through a CI sludge filter press with the overflow back to the pumping sump. When necessary, the sludge is hauled away for disposal.

Generic Flow Chart